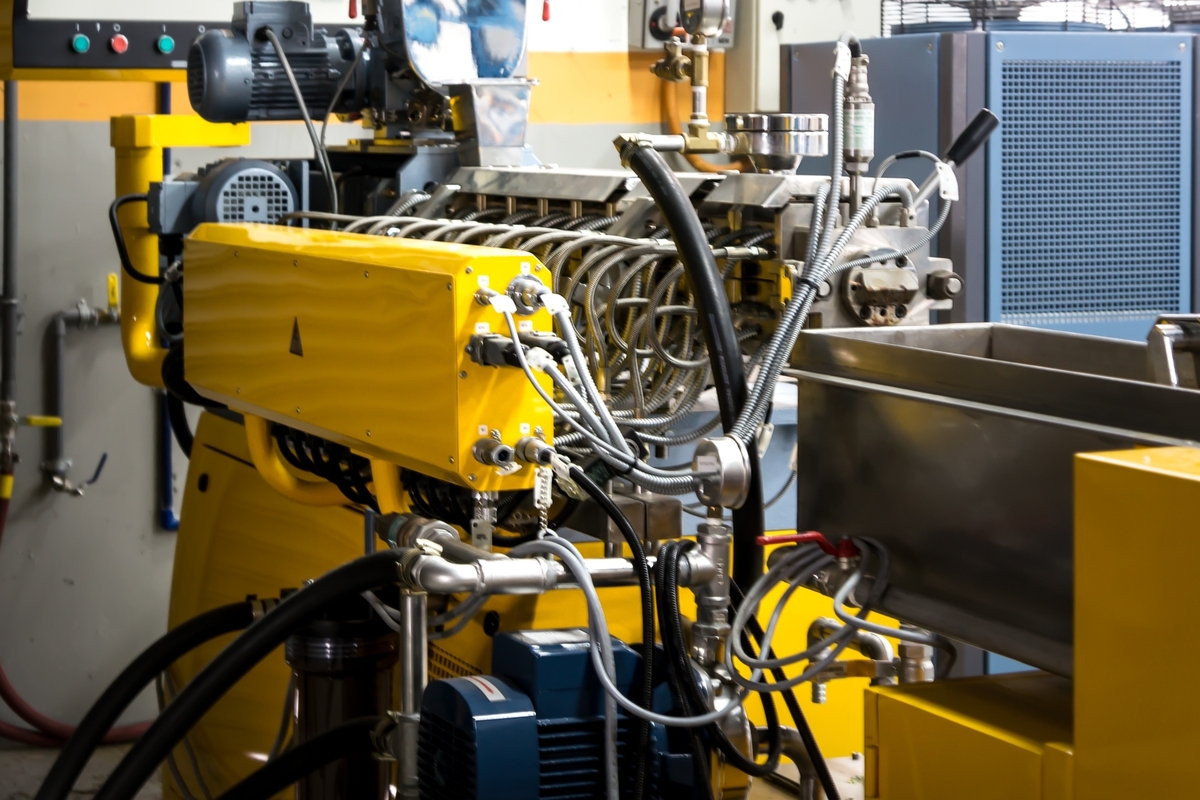

Explore The Types and Prices of PVC Extrusion Machines Available In Mexico

PVC extrusion machines are indispensable in the plastic manufacturing industry, particularly for producing a wide range of plastic products such as pipes, profiles, and sheets. Mexico, being a significant player in the plastic manufacturing sector, offers a diverse array of PVC extrusion machines suitable for various industrial applications. This article aims to provide a comprehensive overview of the types of PVC extrusion machines available in Mexico, along with their respective prices, to guide potential buyers in making informed decisions.

1. Single Screw Extruders

Overview:

Single screw extruders are among the most commonly used PVC extrusion machines. They consist of a single helical screw rotating within a cylindrical barrel, which pushes the PVC material through a die to form the desired shape.

Advantages:

– Cost-effective for basic PVC extrusion tasks.

– Easy to operate and maintain.

– Suitable for producing pipes, sheets, and simple profiles.

Price Range:

In Mexico, single screw extruders are available starting from $20,000 to $80,000, depending on the machine’s capacity, brand, and additional features.

2. Twin Screw Extruders

Overview:

Twin screw extruders feature two intermeshing screws that provide better mixing and material handling capabilities, making them ideal for processing PVC mixtures with additives.

Advantages:

– Enhanced mixing and homogenization of material.

– Higher output and efficiency compared to single screw extruders.

– Suitable for producing complex profiles and high-quality pipes.

Price Range:

Prices for twin screw extruders in Mexico range from $50,000 to $150,000. The cost varies based on the machine’s screw configuration, brand, and output capacity.

3. Conical Twin Screw Extruders

Overview:

Conical twin screw extruders are designed with conical screws that gradually increase in diameter, providing better feeding and mixing properties, especially for processing PVC compounds.

Advantages:

– Improved material feeding and melting efficiency.

– Ideal for producing large diameter pipes and complex profiles.

– Energy-efficient design.

Price Range:

In Mexico, conical twin screw extruders are priced between $60,000 and $180,000, depending on the machine’s specifications and manufacturer.

4. Parallel Twin Screw Extruders

Overview:

Parallel twin screw extruders feature parallel screws that rotate in the same direction, offering excellent material conveying and dispersion capabilities.

Advantages:

– Consistent and efficient material processing.

– Suitable for producing high-quality PVC profiles and sheets.

– High throughput and energy efficiency.

Price Range:

Prices for parallel twin screw extruders in Mexico range from $70,000 to $200,000, varying with the machine’s capacity, brand, and technological features.

5. High-Speed PVC Extrusion Machines

Overview:

High-speed PVC extrusion machines are designed for high-volume production and increased operational efficiency. These machines are equipped with advanced technology to support rapid extrusion processes.

Advantages:

– Significantly higher production rates.

– Advanced control systems for precise operations.

– Suitable for large-scale manufacturing of PVC products.

Price Range:

In Mexico, high-speed PVC extrusion machines are available from $100,000 to $300,000, depending on the machine’s speed, capacity, and additional technological features.

6. Compact PVC Extrusion Machines

Overview:

Compact PVC extrusion machines are designed for small to medium-sized production units, offering a space-saving solution without compromising on efficiency.

Advantages:

– Space-efficient design for smaller industrial setups.

– Cost-effective for medium-scale production.

– Easy to install and operate.

Price Range:

These machines in Mexico are priced between $15,000 and $50,000, based on the machine’s capacity, features, and manufacturer.

Choosing the right PVC extrusion machine is crucial for optimizing production efficiency and ensuring the quality of the final PVC products. With a variety of options available in Mexico, ranging from single screw extruders to high-speed and compact machines, businesses can select machines that best fit their production requirements and budget.

When considering the purchase of a PVC extrusion machine, it’s essential to evaluate factors such as production capacity, material handling capabilities, energy efficiency, and overall cost. Moreover, engaging with reputable manufacturers and suppliers in Mexico will ensure access to high-quality machines, reliable after-sales support, and necessary maintenance services.

By understanding the types and prices of PVC extrusion machines available in Mexico, businesses can make informed decisions to enhance their production capabilities and stay competitive in the plastic manufacturing industry.

References

Please note that the prices mentioned are estimates and may vary based on the supplier, custom configurations, and market conditions. For accurate pricing and the latest models, it’s advisable to consult with local suppliers and manufacturers.

This article is intended for informational purposes only and should not be construed as professional advice. Always consult with a qualified expert or industry professional before making any investment decisions.