Understanding the Cost of Hydraulic Cylinders in Mexico

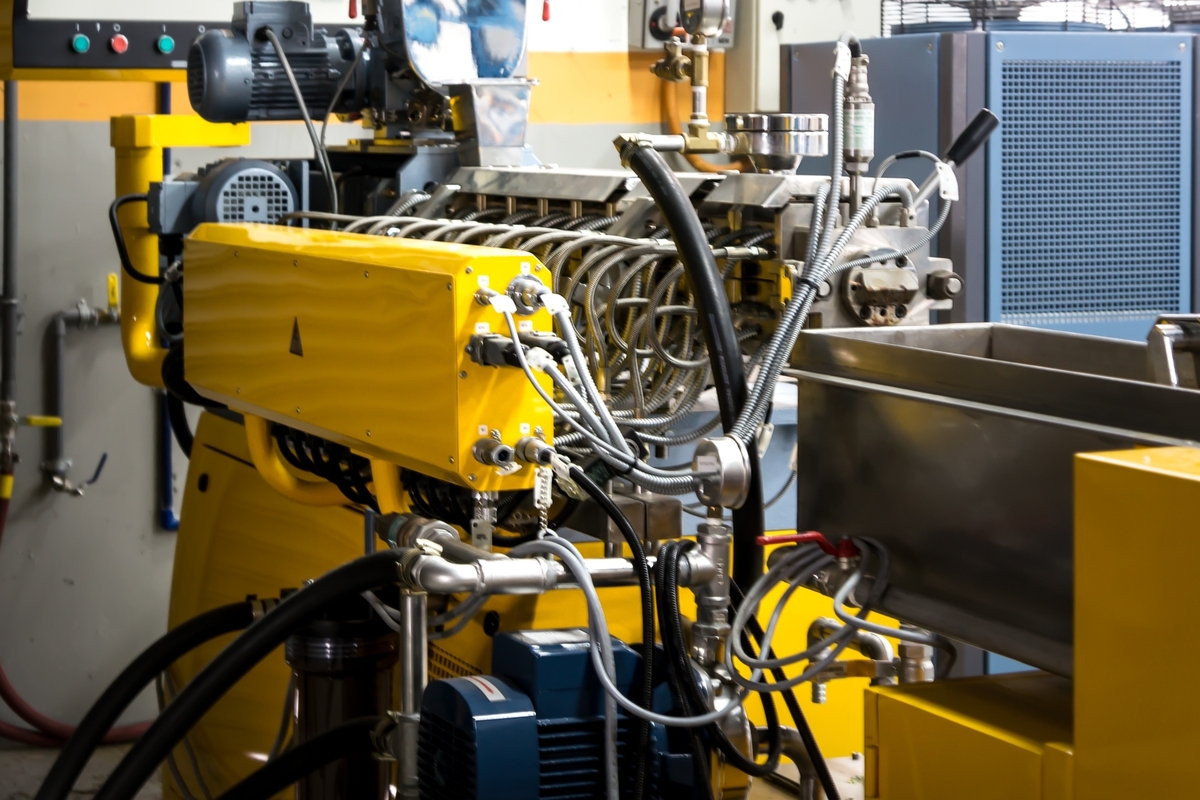

Hydraulic cylinders play a crucial role in numerous industries, providing the mechanical power needed to perform a wide array of tasks ranging from excavating to lifting and pushing heavy loads. Businesses in Mexico that rely on machinery and equipment powered by hydraulic systems face the important decision of procuring the right hydraulic cylinders that fit their needs and budget. In this article, we will delve into various factors influencing the cost of hydraulic cylinders in Mexico, explore different types and their applications, and provide insights into sourcing and maintenance considerations.

Factors Influencing Hydraulic Cylinder Costs

The price of hydraulic cylinders in Mexico is influenced by multiple variables:

1. Type of Hydraulic Cylinder

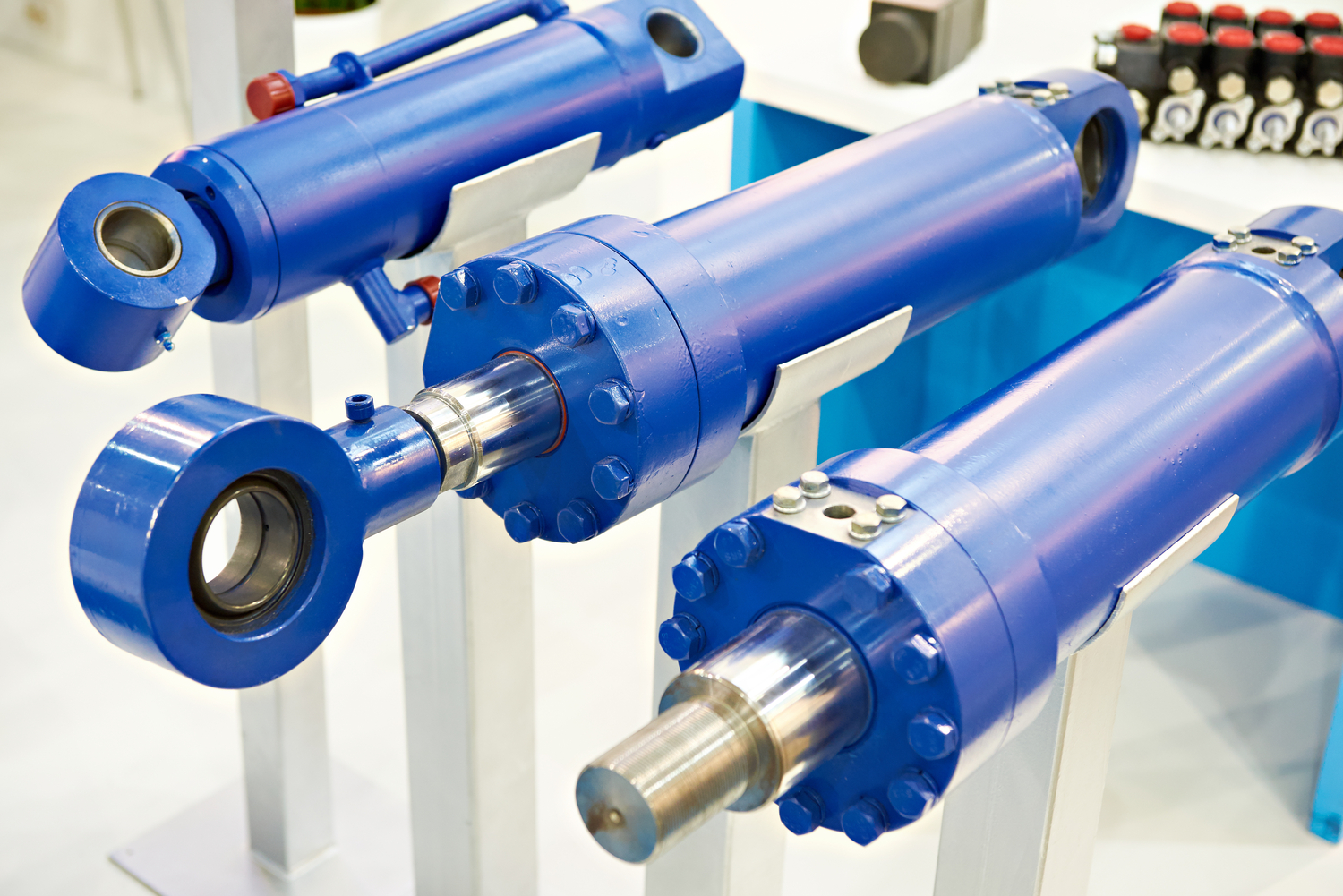

There are different types of hydraulic cylinders, each with specific characteristics and tailored for diverse applications:

Tie-Rod Cylinders: These are commonly utilized in industrial and manufacturing sectors due to their robust construction and ease of maintenance.

Welded Cylinders: Known for their compact design, welded cylinders are ideal for mobile machinery like agricultural and construction equipment.

Telescopic Cylinders: Used in applications requiring extended reach, such as dump trucks and cranes.

Double-Acting Cylinders: Employed for applications where force is needed in both extending and retracting the cylinder.

2. Material and Construction Quality

Hydraulic cylinders are typically made from high-strength steel, although stainless steel and aluminum options are available for specific use-cases. High-quality materials and robust construction result in longer-lasting cylinders but also come at a higher cost.

3. Design Specifications

Customization in terms of size, stroke length, mounting styles, and operational pressure ratings can add to the cost. Standard off-the-shelf models are generally cheaper compared to highly specialized custom designs.

4. Manufacturing Brand

Renowned brands known for reliability and superior performance command higher prices due to their established reputation and advanced manufacturing techniques. However, opting for well-known brands can be a worthwhile investment to ensure durability and after-sales support.

5. Import Duties and Taxes

Importing hydraulic cylinders into Mexico may involve various duties and taxes, which can significantly impact the final price. Locally manufactured cylinders may offer cost advantages by avoiding these additional charges.

6. Volume and Order Size

Bulk purchases often come with discounts, resulting in lower per-unit costs. Larger orders might also offer negotiation leverage on price and delivery terms.

Average Cost Range

Given the diverse factors at play, the cost of hydraulic cylinders in Mexico can vary widely. As an illustrative guide:

Standard Tie-Rod Cylinders: Typically range from $50 to $300 USD per unit.

Welded Cylinders: Can cost between $100 to $800 USD, influenced by size and pressure rating.

Telescopic Cylinders: Due to their complexity, these can start from $500 and go up to several thousand USD.

Custom-Specified Cylinders: Custom builds tailored for specific requirements can exceed $1,000 USD per unit.

Sourcing Hydraulic Cylinders in Mexico

When sourcing hydraulic cylinders in Mexico, businesses have several options:

1. Local Manufacturers

Purchasing directly from local manufacturers can save on import duties and offer the advantage of localized customer support and faster delivery. Some well-known Mexican manufacturers include:

Hydraulics Mexico

Cilindros Hidráulicos S.A.

HydrauMex

2. International Manufacturers and Importers

For specialized needs, businesses may turn to international manufacturers renowned for their expertise in hydraulic systems. Importers often serve as intermediaries to help navigate the intricacies of customs and logistics.

3. Authorized Distributors and Dealers

Many global brands have authorized distributors in Mexico who provide sales, service, and warranty support. This can ensure the authenticity of products and reliability of after-sales services.

4. Online Marketplaces

B2B marketplaces and e-commerce platforms offer another avenue for sourcing hydraulic cylinders. These platforms can provide access to a variety of suppliers and product options with competitive pricing.

Maintenance Considerations

Regardless of the cylinder type or source, maintaining hydraulic cylinders is essential for longevity and performance. Regular inspections for signs of wear, proper lubrication, timely seal replacements, and adherence to manufacturer guidelines can significantly extend the service life of hydraulic cylinders. Investing in high-quality cylinders and maintenance can reduce the risk of equipment downtime and costly repairs in the long run.

Conclusion

Understanding the cost structure and various factors influencing the price of hydraulic cylinders in Mexico is vital for businesses aiming to make informed procurement decisions. By considering the type of cylinder, material quality, customization needs, and reliable sourcing channels, companies can optimize their hydraulic systems for efficiency, reliability, and cost-effectiveness. Maintenance should not be overlooked as it plays a crucial role in ensuring the operational longevity of these indispensable components.